Centreville, Virginia

Community Resource Page

At Luck Companies, our values are more than cultural expectations; they are the principles of the way we operate our businesses.

Takes personal responsibility for the success of self, others, and the organization

Earns the trust and respect of others

Delivers ideas and innovation that add value

Ignites human potential and performance

Centreville, Virginia

Community Resource Page

As a prudent multi-generation family-owned and operated business we are currently developing detailed restoration plans for our iconic Fairfax Plant which positively impacted customers and communities in Fairfax County for almost 90 years.

We take a long-term, thoughtful approach to this work and hold ourselves to the highest standards by planning for the restoration of our sites, the welfare of the environment, and the safety and prosperity of our associates, customers, and communities.

At Luck Stone/Companies we integrate environmental, economic, and social responsibility best practices into our business strategies to ensure the long-term health of our company, our people, our communities, and our environment.

Special Permit Amendment Update

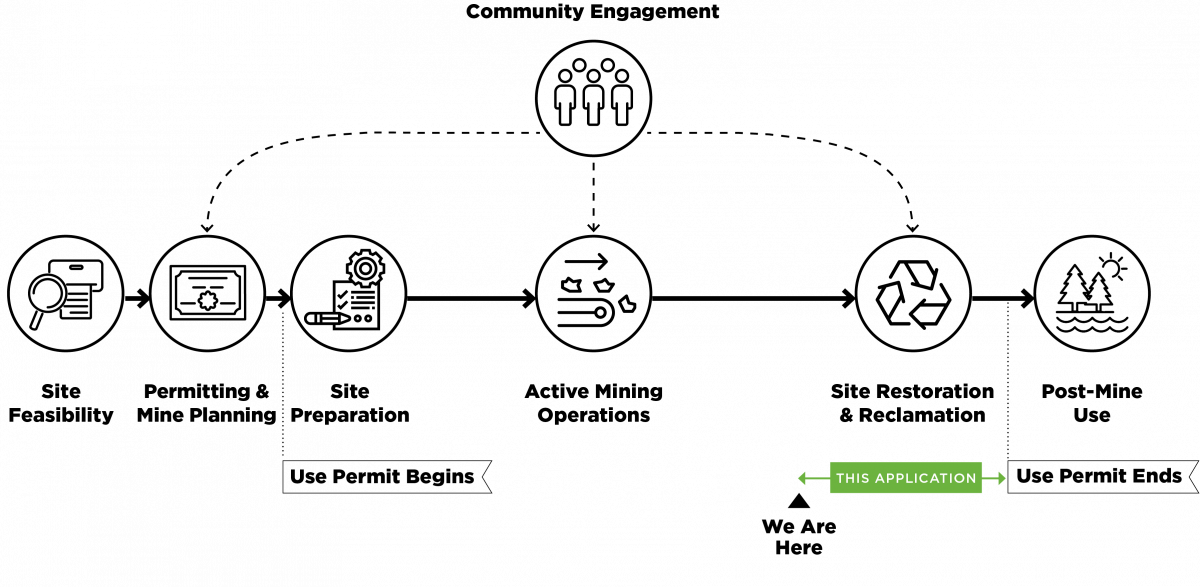

Our Fairfax plant has successfully operated in Fairfax County since the 1930’s. For the past 40 years we’ve effectively maintained a Special Permit issued by the Board of Zoning Appeals (BZA) of Fairfax County which is subject to renewal every five years. Our most recent renewal application (SPA 81-S-064-11) originally submitted in June of 2018, included details about anticipated reclamation and site restoration efforts as production mining in our North Pit was planned to cease.

Upon an engaging session with the community in October of 2018 we spent several months developing a highly effective and environmentally friendly Reclamation Fill Plan to provide more detail on how we plant to restore the property. As we have just recently received feedback from the County and their third-party review firm, we are nearing the completion of a final draft of the plan and are excited to share our progress.

Our permitting team is dedicated to disseminating this information to our community in creative and innovative ways during these challenging times, therefore, we have developed this Community Resource Page as a tool for the benefit our friends and neighbors. Below, in our FAQ section, you’ll find answers to several of the questions we’ve received from the community in regard to our intended reclamation efforts.

We encourage you to review the information below, continue to ask good questions and stay engaged through this process.

Upcoming Events:

Recording of Community Webinar held on June 25, 2020 (password: Luck062520)

Fairfax County Board of Zoning Appeals Hearing - July 22, 2020 at 9am

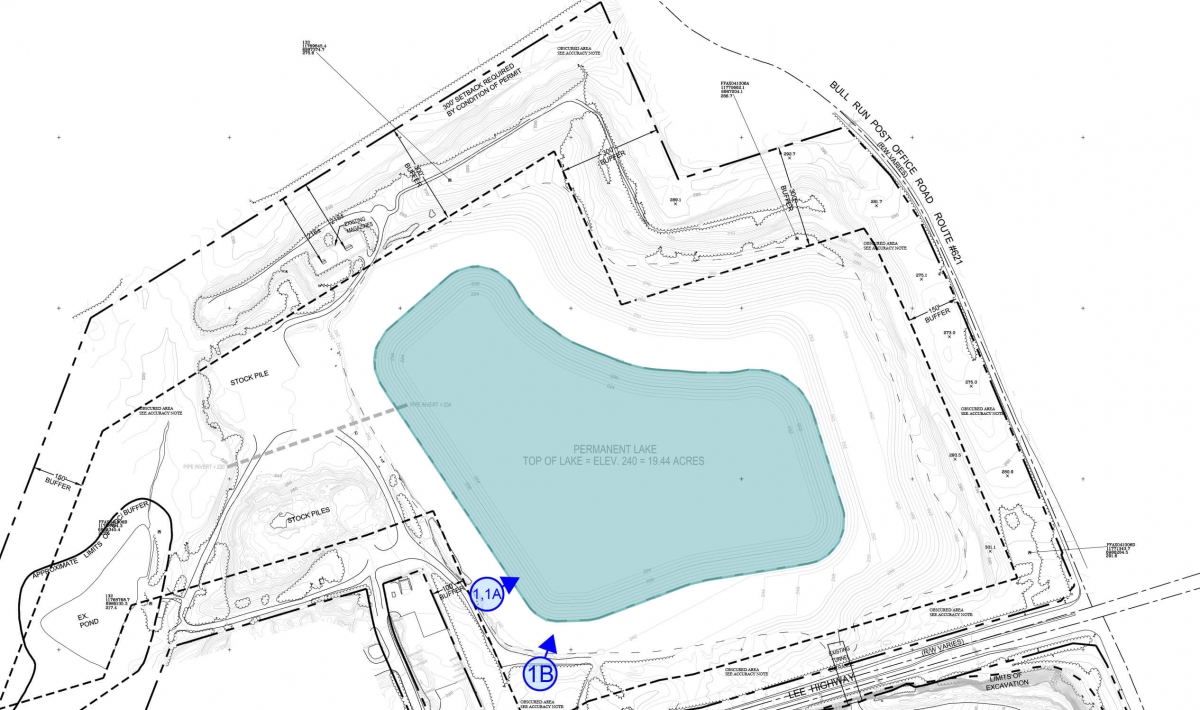

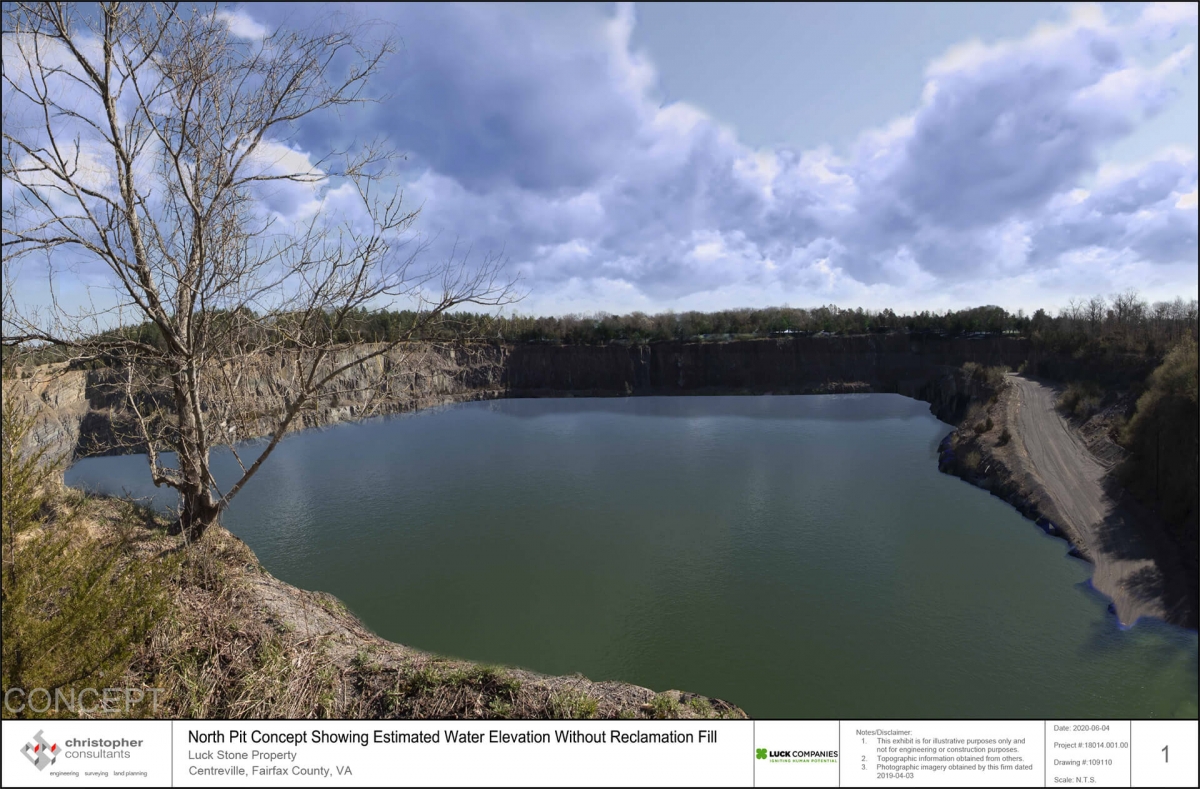

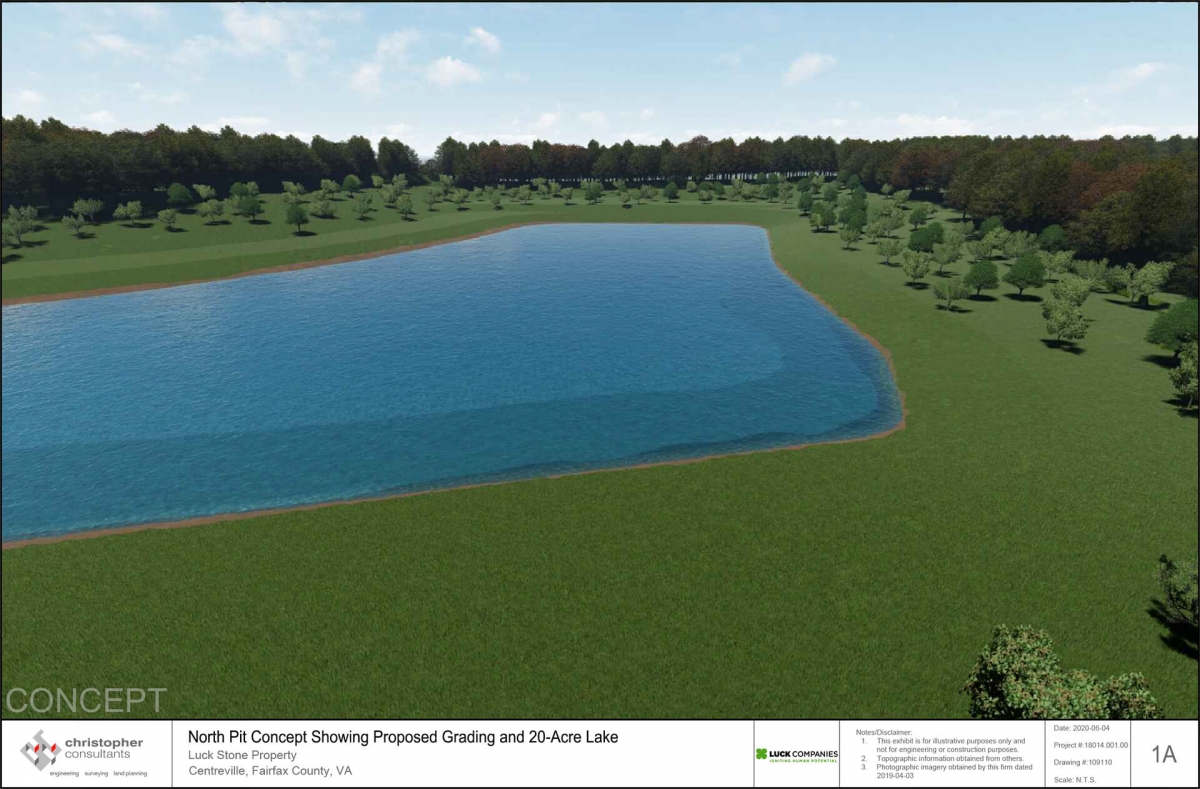

Reclamation is the critical and final element of the mining process which can take many forms. Being located in a suburban environment like Fairfax County, the reclamation of our Fairfax Plant has been carefully evaluated and planned with great detail to ensure the safety of our neighbors, compatibility with the surrounding landscape and with the ultimate goal of a resulting property that is safe and suitable for a new beginning. As depicted below, rather than left to naturalize without any further restoration efforts, upon completion of our Reclamation Fill exercise beginning in our North Pit, the property will be free of accessible highwalls and be suitable for a variety of redevelopment opportunities. The approximate 20-acre lake will be complemented with gentle slopes traversing downward from preserved vegetation along the perimeter of the property. The meticulous restoration of an exhausted quarry pit to a property poised for a new beginning will be an incredible transformation that western Fairfax County deserves.

Luck Stone operates under a Special Use Permit to conduct mining activity on the property, currently zoned Residential-Conservation (“RC”). Luck Stone is requesting a five-year renewal of SPA 81-S-064 to permit continuation of its existing stone quarrying use on the Property as well as the initiation of restoration efforts beginning in the North Pit, in which Luck Stone has now ceased production mining efforts. The renewal application does not request any change to the site’s existing quarrying use, nor is Luck Stone attempting to define the end-use of the Property at this time. Luck Stone’s application does not propose a landfill, recycling center, or mixed waste center – none of which are permitted in the RC zoning district.

Reclamation is the final (and integral) phase of the quarrying process and, if effectively achieved, should restore the Property to a “pre-mining” condition in which a post-mining use can be implemented. The reclamation process for this quarry includes cessation of mining activities, removal of equipment, aggregate stockpiles, and certain structures, filling the quarry with Reclamation Fill from the bottom up, testing the material for compliance with the Reclamation Plan, smoothing the edges of the quarry rim where feasible, maintaining the fence around the quarry perimeter, revegetating the site, and conducting all necessary inspections in accordance with the applicable regulations promulgated by the County and DMME.

The reclamation process is distinguishable from determining post-mining uses. While previous concepts (including the 2008 Special Permit Amendment plat) proposed public water storage with accompanying conceptual recreational facilities as the post-mine use, such concepts have been more thoroughly evaluated and Luck Stone has determined that none of the local public water suppliers have interest in taking ownership of the pits for use as a municipal reservoir. Consequently, Luck Stone has removed the previously-proposed public water storage reuse plan from its plan set and is now proposing to revegetate the site and ultimately construct two approximately 20-acre surface lakes in general location of the existing pits which will make the site available for uses under the property’s RC zoning district.

Luck Stone, as the quarry’s owner and operator, bears the ultimate responsibility to safeguard its employees and the local community throughout all phases of the quarrying process, including the reclamation process. Va. Code Ann. § 45.1-180 and DMME require Luck Stone to restore the site to a stable, safe, and environmentally-friendly condition that presents opportunities for future post-mining uses. While a reservoir reuse plan for public water supply was depicted on the 2008 SPA plat, Luck Stone has determined that there is no longer interest from adjacent water purveyors to acquire the property for that application. Furthermore, based on the results of recent hydrogeological studies, if left to naturally fill it is expected that there would be exposed highwalls of approximately 125 feet above the permanent water surface elevation.

Given the information above, and as a responsible quarry operator for almost 100 years, Luck Stone now plans to restore the property utilizing the common restoration practice of using pre-screened Reclamation Fill to backfill the exhausted pit(s), beginning with the North Pit. This technique will ultimately eliminate exposed highwalls by implementing gentle fill slopes leading into an approximately 20-acre lake feature that will also be designed to provide water quantity and quality control for the drainage shed.

Upon completion of successful restoration efforts as proposed, satisfactory inspections performed by appropriate agencies and ultimate release of the county-held bond, the property would be available for future redevelopment in the RC zone via a separate land development application process.

Luck Stone estimates that the North and South pits have a potential maximum amount of cubic yardage storage capacity for reclaimed fill of approximately 13 million yd3 and 14.5 million yd3, respectively. We anticipate that it will take approximately 20 years to complete fill activities and revegetate the North Pit.

Because the South Pit will continue operating for the foreseeable future, it is Luck Stone’s intention to amend the Reclamation Plan as necessary prior to beginning reclamation efforts in the South Pit. Once reclamation efforts begin in the South Pit, the restoration work may last for approximately 23 years, subject to availability of qualifying Reclamation Fill.

Luck Stone notes that the above timeframes are merely estimates; a variety of factors will influence the timing of completion of the reclamation process including, but not limited to: (1) market conditions for the purchase of aggregates, which will influence the timeframe for cessation of mineral extraction activities in the South Pit; (2) market conditions regarding the availability of Reclamation Fill which meets or exceeds the standards set forth in the Plan; (3) the time needed to revegetate the site to a suitable level of vegetative maturity; and (4) whether a final reuse/end use of the site (other than a general restoration of the site as Luck Stone has proposed) is determined during implementation of the Reclamation Plan which merits a revised reclamation approach.

Luck Stone anticipates construction of an approximately 20-acre lake having a maximum depth of up to 20 feet. The anticipated water surface elevation is 240 feet for the North Pit, and though the Reclamation Plan has not yet been amended for the South Pit, Luck Stone anticipates the water surface elevation will be approximately 214 feet for the South Pit. Final water surface elevations of the stormwater facilities are subject to minor adjustments and will be finalized through the site plan process prior to the final phase of reclamation.

Upon successful completion of restoration efforts, ultimately resulting in revegetated operational land and an approximately 20-acre lake in the North Pit the property will be available for other uses under the RC zoning district or other uses as permitted through the various entitlement processes permitted in the county. The lake, as planned, may have capabilities for passive and/or recreational uses, however, the specific use for the water body, beyond water quantity and quality control, will be determined as part of a future land use application.

Luck Stone prides itself on maintaining a clean entrance and ensuring trucks exiting the Property are not tracking mud and aggregates onto Lee Highway. Pursuant to existing Condition 24, Luck Stone routinely operates a water truck which sprays down the existing entrance along Lee Highway and internal quarry roads to reduce the potential for mud, debris, and dust. The existing quarry contains a wheel wash system in which all outgoing trucks must utilize.

24. Roads or other areas subject to traffic within the confines of the quarry shall be watered as often as necessary to control dust.

Luck Stone neither owns nor operates its own fleet of on-road dump trucks, nor has Luck Stone been made aware of any specific incidents concerning quarry-related trucks which disobeyed traffic laws in the vicinity of the quarry. The company cannot assume responsibility for driver behavior once it exits the Property. Moreover, given that the quarry is approximately one mile from the referenced intersection and that there are several industrial operators in the vicinity of the quarry which have customers utilizing dump trucks, it may be difficult to determine whether any given speeding or unsafe truck originated from the quarry.

That said, safety at all phases of the quarrying process is Luck Stone’s top priority, and the company takes such concerns and driver behavior seriously. Luck Stone’s internal policies require all commercial drivers to engage in on-site training prior to entering the mine site beyond the scale office.

As noted in draft Conditions 51 and 52, Luck Stone will: (1) promptly investigate any specific traffic complaints at the time of the incident; (2) appoint an internal coordinator to address issues of neighborhood concern and provide the coordinator’s name and contact information (including email and phone number) to the registered agents/presidents of nearby homeowner associations (e.g., Virginia Run, Stonebridge at Bull Run Winery, Gate Post Estates, Stuart’s Crossing, etc.) and to the office of the Sully District Supervisor, to whom any written concerns may be submitted; and (3) post a sign at the quarry exit in English and in Spanish instructing drivers to obey all posted speeds and laws.

51. The Applicant will appoint an internal coordinator to address issues of neighborhood concern, and shall provide the coordinator’s name and contact information (including email and phone number) to the registered agents/presidents of nearby homeowner associations (e.g., Virginia Run, Stonebridge at Bull Run Winery, Gate Post Estates, Stuart’s Crossing, etc.) and to the office of the Sully District Supervisor, to whom any written concerns may be submitted. The internal coordinator will offer to meet with neighboring citizens and homeowner’s association groups on an annual basis to discuss concerns regarding traffic management, maintenance of vegetation, noise, dust and debris, and other matters of mutual concern.

52. The Applicant will investigate any specific traffic complaints and will post a sign at the quarry exit in English and in Spanish instructing drivers to obey all posted speeds and laws. The Applicant shall post signage at the site exit which states that, except for local deliveries, trucks are to refrain from using Bull Run Post Office Road (Route 621).

As noted above, Luck Stone neither owns nor operates its own fleet of on-road dump trucks. The company cannot assume responsibility for driver behavior once it exits the Property. However, Luck Stone supports the re-imposition of a through-truck restriction on Bull Run Post Office Road. Luck Stone has also proposed draft Condition 52 which commits it to posting signage on the Property stating that, with the exception of local deliveries or Reclamation Fill sources on Bull Run Post Office Road, trucks are to refrain from using Bull Run Post Office Road as a cut through to and from Loudoun County.

52. The Applicant will investigate any specific traffic complaints and will post a sign at the quarry exit in English and in Spanish instructing drivers to obey all posted speeds and laws. The Applicant shall post signage at the site exit which states that, except for local deliveries, trucks are to refrain from using Bull Run Post Office Road (Route 621).

Luck Stone welcomes feedback, but is unaware of any formal complaints or concerns. Luck Stone requests that any documented claims that the quarry has affected adjacent wells should be made immediately and formally in writing to Luck Stone at the time of alleged impact. Luck Stone will work with the concerned citizen and investigate the complaint as we have done with any presented concerns in the past. As depicted on Sheet 2 of the SPA Plat (link above), Luck Stone is to install two new monitoring wells between the North Pit quarry and adjacent homes in the Stonebridge at Bull Winery residential subdivision. These new wells, in addition to the several others in the vicinity of the quarry will be utilized during ongoing groundwater quantity and quality monitoring throughout the reclamation process.

Luck Stone is amenable to reestablishing this citizen liaison group, and has proposed a condition to this effect. As noted in draft Condition 51, Luck Stone will appoint an internal coordinator to oversee the liaison group, and shall provide the coordinator’s name and contact information (including email and phone number) to the registered agents/presidents of nearby homeowner associations (e.g., Virginia Run, Stonebridge at Bull Run Winery, Gate Post Estates, Stuart’s Crossing, etc.) and to the office of the Sully District Supervisor. Luck Stone will offer to meet with neighboring citizens and homeowner’s association groups on an annual basis to discuss concerns regarding traffic management, maintenance of vegetation, noise, dust and debris, and other matters of mutual concern.

51. The Applicant will appoint an internal coordinator to address issues of neighborhood concern, and shall provide the coordinator’s name and contact information (including email and phone number) to the registered agents/presidents of nearby homeowner associations (e.g., Virginia Run, Stonebridge at Bull Run Winery, Gate Post Estates, Stuart’s Crossing, etc.) and to the office of the Sully District Supervisor, to whom any written concerns may be submitted. The internal coordinator will offer to meet with neighboring citizens and homeowner’s association groups on an annual basis to discuss concerns regarding traffic management, maintenance of vegetation, noise, dust and debris, and other matters of mutual concern.

Nationally, the open pit quarry reclamation process is a relatively rare event given that industrial hard-rock quarry operations of similar size to the Fairfax Plant (most of which commenced in the early 1900s) are just recently approaching the end of their mineral reserve life. Reclamation activity in which reclamation materials are used is, however, occurring throughout the mid-Atlantic including at the Loudoun Quarries in Loudoun County and Allan Myers Quarry in Devault, Pennsylvania.

The Fairfax Plan reclamation effort represents Luck Stone’s first large-scale, hard-rock quarry closure. Accordingly, the company believes it important to provide sufficient detail, protocol, and protections in the Reclamation Plan that ensures a model reclamation effort that exceeds DMME requirements for a non-waivered county, is environmentally sensitive, and protects groundwater resources.

Despite being the first large-scale quarry reclamation effort (a characteristic shared by several commercial quarry operators), Luck Stone is well-positioned to lead such an endeavor for three reasons. First, with nearly a century of experience, Luck Stone is the nation’s largest family owned and operated producer of crushed stone, sand, and gravel. The company is proud of its mineral extraction and environmental record, and was recognized in 2018 as the overall winner by DMME and the Virginia Transportation and Construction Coalition (“VTCC”) for its exemplary efforts in restoring land disturbed by mining to an environmentally-friendly and useable state after mining is complete.

Second, Luck Stone has gained reclamation experience through its closure of several sand and gravel quarries/pits it owns, as well as implementing reclamation and reuse plans at its Leesburg Plant (which will be used as a reservoir for Loudoun Water) and at its Atlanta-Stephens plant in Georgia (which is permitted as a construction and demolition debris landfill). Furthermore, Luck Stone moves millions of yards of fill material each year as part of daily quarrying activities. The Company imports material at a number of sites in accordance with DMME regulations, including at its Bull Run Plant, located just a few miles north of the Fairfax Plant in Loudoun County. Testing protocols and procedures have been established for these exercises which will be carried over and enhanced for the proposed reclamation work at Fairfax.

Third, and as it has done throughout its corporate history to ensure the best possible expertise, Luck Stone has engaged professional consultants (HHNT and ECS) which possess significant expertise in quarry reclamation plans, groundwater resources, and hydrology. These consultants have worked with Luck Stone to prepare the enclosed Reclamation Plan. The Reclamation Plan is intended to govern all aspects of the proposed reclamation effort in the North Pit including the classification of material to be placed, the source of said material, screening, sampling, and testing protocols, material placement and compaction, site access and maintenance, groundwater monitoring protocols, site inspection, reporting procedures, chain of custody protocols, grading plans, soil and chemical testing requirements, soil submittal and approval processes, record keeping, and more. As proposed by draft Condition 53, Luck Stone requests the Reclamation Plan be incorporated by exhibit into the development conditions.

53. The Applicant shall adhere to the Reclamation Fill Plan dated July 26, 2019, prepared by ECS Mid-Atlantic, LLC and Hodges, Harbin, Newberry & Tribble, Inc., and incorporated as Exhibit A to these conditions. The Reclamation Fill Plan may be updated and amended as necessary, without a Special Permit Amendment, if such changes are approved by DPWES and LDS. Pursuant to the Reclamation Fill Plan, the Applicant will retain all screening, testing, sampling, and monitoring records, as well as delivery schedules, and will either provide such records to the County as requested.

Luck Stone expects the tunnel to remain open through the duration of the reclamation process until both the North Pit and South Pit approach their final stages of filling (whichever is first in time). At that point, which may be several decades in the future, plans will be developed in accordance with VDOT to permanently plug the tunnel. As part of the reclamation efforts taking place at Luck Stone’s Leesburg Plant, Luck is currently involved with Loudoun Water in the implementation of a tunnel plug of similar size.

What is the imperative to request a change to the reclamation plan at this stage?

Even under the 2008 reclamation plan, renewed in 2013, the proposed contours in the North Pit and South Pit necessarily inferred the importation of some level of unspecified reclamation materials. This application seeks to clarify what those reclamation materials will consist of, clarify that the quarry will not be used for reservoir purposes, and that the reclamation process will not commence until all necessary studies, protocols, and processes have been developed and approved by all relevant local, state, and federal agencies.

Proper quarry reclamation planning is critical to adhering to state DMME requirements. It is also important in terms of the public’s acceptance of quarrying, generally, and demonstrates that former quarry sites can provide environmental and economic value to communities. Having an accurate reclamation plan which reflects reality is important from an expectations, liability, and transparency perspective.

Oftentimes, and as is the case here, the reclamation process is multi-generational in nature. As noted above, the total projected timeframe for completion of the proposed Reclamation Plan, and deliver the site in a revegetated state, may take 20 years (or longer) from the end of mineral extraction activities (or 40 or more years from today). Because mineral reserves in the North Pit may be exhausted during the life of the current permit request, Luck Stone believes it is important to provide a reclamation plan now—to allow it to begin preparing for future reclamation activities.

The Reclamation Plan reflects updated studies and changes which have occurred since 2008—namely that the prior reservoir/lakefront recreational reuse plan depicted on the 2008 SPA plat is longer practical. In the event the Board were to renew Luck Stone’s special permit request without altering the prior plan, the Board would be approving a reuse plan that is both misleading and fails to contemplate the protocols necessary to ensure that reclamation efforts are conducted in an environmentally responsible manner.

The Applicant has held discussions with representatives of the Prince William Service Authority. At this time, the Service Authority has no interest in using the quarry for reservoir purposes. Furthermore, Luck Stone has separately arranged public water storage opportunities with Loudoun Water by way of their quarries the Leesburg and Ashburn area.

As it has done throughout its corporate history, and to ensure the best possible expertise, Luck Stone has engaged professional consultants (HHNT and ECS) which possess significant expertise in reclamation plans, groundwater resources, and hydrology. These consultants have worked with Luck Stone to prepare the enclosed Reclamation Plan. The Reclamation Plan is intended to govern all aspects of the proposed reclamation effort in the North Pit including the classification of material to be placed, the source of said material, screening, sampling, and testing protocols, material placement and compaction, site access and maintenance, groundwater monitoring protocols, site inspection, reporting procedures, chain of custody protocols, grading plans, soil and chemical testing requirements, soil submittal and approval processes, record keeping, and more. As proposed by draft Condition 53, Luck Stone requests the Reclamation Plan be incorporated by exhibit into the development conditions.

Luck Stone’s goal is to provide a model reclamation effort that exceeds DMME requirements for a non-waivered county, is environmentally sensitive, protects groundwater resources, and serves as a model for future reclamation plans elsewhere. Luck Stone will continue working with staff to determine the appropriate level of detail required for such a reclamation plan.

53. The Applicant shall adhere to the Reclamation Fill Plan dated July 26, 2019, prepared by ECS Mid-Atlantic, LLC and Hodges, Harbin, Newberry & Tribble, Inc., and incorporated as Exhibit A to these conditions. The Reclamation Fill Plan may be updated and amended as necessary, without a Special Permit Amendment, if such changes are approved by DPWES and LDS. Pursuant to the Reclamation Fill Plan, the Applicant will retain all screening, testing, sampling, and monitoring records, as well as delivery schedules, and will either provide such records to the County as requested.

Reclamation Fill for the purposes of the Luck Stone Fairfax Plant will refer to natural (i.e. soil and rock) materials that are certified to meet the requirements of this plan which have been developed to be protective of the environment and human health. Reclamation Fill will include earthen and rock materials that have not been known to be exposed to, or mixed with, solid waste, petroleum products, or chemical contaminants. Only materials that meet these criteria and satisfy the testing requirements defined later in this document will be accepted on site and used as Reclamation Fill.

Given similar geologies that exist across Northern Virginia and Maryland, where it is anticipated such dirt and rock would come from, it is fair to say that the geology would be similar to the geology in the vicinity of the quarry.

Given that the Reclamation Fill will consist of uncontaminated, non-water soluble, non-decomposable, inert solid material, wildlife, pests, and birds are not expected to the attracted to the Property any more than under current conditions.

Luck Stone will conduct a due diligence review for each source of Reclamation Fill prior to acceptance at the Luck Stone Fairfax Quarry. A Phase I Environmental Site Assessment (ESA) report (if available) or similar documents/research will be provided by the generator with the initial Reclamation Fill Profile and Agreement (Profile). Luck Stone personnel, or a third-party qualified consultant, may visit the Reclamation Fill source location as necessary in-person and/or conduct a desktop study of historical use of the property to determine if there is evidence of a release of solid waste, petroleum products, or chemical contaminants.

Regardless of the due diligence review, Luck Stone will require all Reclamation Fill generators to characterize the material to meet the requirements set forth in this plan. A qualified third-party consultant will be required to sample and conduct analytical testing on the Reclamation Fill material being considered for importation to the Luck Stone site. A grab soil sample representative of the Reclamation Fill to be brought to the site will be submitted for laboratory analysis of Column A Phase I Priority Analytes. Testing will be done at the source and the results will be included with the Profile submitted for review and approval by Luck Stone prior to transporting any Reclamation Fill to the Luck Stone site.

The acceptance application will include soil sampling results at a rate of one grab sample per 3,000 cubic yards of Reclamation Fill per source of material. Following the initial application approval, the generator will be required to provide supplemental laboratory results at a rate of one grab sample per each additional 3,000 cubic yards of Reclamation Fill per source planned for delivery to the site. The generator will be responsible for providing soil sampling results from the material in advance of planned fill delivery.

Samples will be collected by a qualified third-party consultant in appropriate bottle ware and preserved with ice prior to being shipped to a contract laboratory accredited by the Virginia Environmental Laboratory Accreditation Program. Sampling and analytical methods will conform to the methods described in the U.S. Environmental Protection Agency’s SW-846 document (EPA, July 2014).

Analytical testing results will be submitted with the Profile for approval by Luck Stone prior to delivery. Luck Stone has the right to request additional analytical testing from the generator for any reason.

As an additional level of quality control, Luck Stone will conduct its own appropriate laboratory testing of Reclamation Fill material, post-delivery, on samples obtained during a random load inspection or if noncompliant materials are suspected during unloading.

The results of analytical testing will be compared to the Groundwater Protection Screening Level (GWPS) criteria set forth in the Ecological and Groundwater Protection Soil Screening levels. Additionally, Luck Stone personnel will collect soil samples in and around the quarry and analyze for inorganic metals to develop a representative, background database for background metals concentrations in the existing soils onsite. These background metals concentrations, if higher than the GWPS, will be the determining criteria for Reclamation Fill acceptance.

If any of the results exceed the limits specified in the Groundwater Protection Soil Screening Level criteria referenced above and exceed background inorganic metals concentrations, the fill will be deemed unfit for acceptance and the generator will be notified.

Luck Stone will require all Reclamation Fill generators to complete and submit an initial Reclamation Fill Profile and Agreement (Profile) for review and pre-approval prior to delivery of the Reclamation Fill to the quarry. The material characterization will be documented on the Profile. The Profile will include the following information:

Laboratory analyses performed by an accredited Virginia Environmental Laboratory will be submitted with the Profile. Upon receipt of a completed Profile, personnel responsible for the Luck Stone’s quarry reclamation project will review the documents and may visit the source site as necessary to visually assess the conditions of the source property. If the Reclamation Fill is approved for acceptance, the Profile will be marked, "Approved", and the applicant will be notified to schedule delivery.

Each delivery to the quarry will be associated with a pre-approved Profile and Shipping Manifest. Deliveries without a pre-approved Profile will not be accepted. Luck Stone will keep all Reclamation Fill Profile records at the quarries or at their corporate offices for the life of the facility. Records may be kept in an electronic format.

Luck Stone will implement a proprietary “QuickHaul” application, which Luck Stone has committed to use for each hauler delivering Reclamation Fill to the site. The application will track the travel route and time for each loaded truck. A Luck Stone associate working within the scale office will verify/back check each delivery vehicle’s travel path and time according to pre-established criteria prior to allowing the truck to enter the site for unloading. In the rare event materials are detected at any stage in the process which do not meet the standards set forth in the Reclamation Fill Plan, or in the event the time lapse between loading at the source generator and delivery to the quarry exceeds established algorithms governing time, traffic, distance, and routes, such materials/vehicles will be immediately removed from the site at the source owner’s expense. Luck Stone is amenable to a condition of approval to this effect.

Luck Stone will retain all screening, testing, sampling, and monitoring records, as well as delivery schedules, and will either provide such records to the County on a set schedule or will agree to make such records available to the County as requested. This commitment is included in draft Condition 53.

53. The Applicant shall adhere to the Reclamation Fill Plan dated July 26, 2019, prepared by ECS Mid-Atlantic, LLC and Hodges, Harbin, Newberry & Tribble, Inc., and incorporated as Exhibit A to these conditions. The Reclamation Fill Plan may be updated and amended as necessary, without a Special Permit Amendment, if such changes are approved by DPWES and LDS. Pursuant to the Reclamation Fill Plan, the Applicant will retain all screening, testing, sampling, and monitoring records, as well as delivery schedules, and will either provide such records to the County as requested.

Luck Stone’s most recent Special Permit renewals in 2008, renewed in 2013, estimated an approximate average of 350 vehicles utilizing the site’s main entrance for mining related activity. As at the current time the majority of stone sales out of the Fairfax Plant have recently been shifted out of its new quarry in Loudoun County, the expected total vehicle count including Reclamation Fill activity is estimated to be the same, with 230 estimated vehicles associated with Reclamation Fill. With opportunities to backhaul stone materials back to the Reclamation Fill source, there may be cases of reduced levels of truck-related activity on roads in the area. According to published VDOT traffic counts, an average of 350 vehicles associated with Luck Stone represents approximately 2 out of every 100 vehicles that pass by the Fairfax Plant on Route 29.